Simply supply compressed air and the unit generates cool air max.65 degC lower than the inlet temperature. No refrigerants (chlorofluorocarbons, etc.) are used.

In the production of various types of equipment, you may have encountered problems of erroneous product accuracy due to inadequate temperature control, fusion and deformation due to heat, short life of cutting tools, and defective functioning of equipment controllers. The air cooling machinery solve these problems to enhance productivity and reduce cost.

Cooling Mechanism

High pressure air supplied from a compressor is discharged at sonic

speed by the eddy current generator in the tangential direction. The air

expands and turns at high speed to become eddy current and moves

in the direction from (A) to (B) in the figure. The adjust valve determines

air quantity (cool air ratio) discharged from the hot air exhaust ports.

The residual air flows, as it is chilled and turns in the same direction as

the outer eddy current, in the direction of cool air outlet (C) through the

inner tunnel that is formed by the centrifugal force of the eddy current.

Cooling Principle

A large centrifugal force acts on the eddy current generated in the unit.

Pressure and density rise sharply and resistance increases to increase

temperature. Turning speed increases and temperature rises the more

on the outside than on the inside, generating a large pressure difference

between the periphery and the center of the eddy current. The air flowing

through the center of the eddy current in the direction from (B) to cool air

outlet (C) does work on the outer eddy current as it expands and loses

its speed (braking action). Temperature rises on the outer side and a low

temperature air is generated at the center. Since quantity of heat supplied

to hot air is always equal to quantity of heat deprived of from cool air,

increasing quantity of heat taken away from the outside through the

adjust valve reduces cool air quantity inside, resulting in a greater

temperature drop.

Features

- No refrigerants and electricity required.

- Super low temperature air is generated as soon as you supply

compressed air.

Jet cool air is at the atmospheric pressure.

Quantity and temperature of cool air are easily adjusted with the

adjust valve screw on the unit. The user can set the required air

quantity and temperature.

The small and light unit is easy to set.

Specially useful for local small-capacity cooling needs.

No mechanical breakdown. Only compressor air is used; no moving

parts are used in the unit.

Provided with a silencer on each of cool air and hot air discharge sides.

Safe for use in areas where use of electricity is prohibited(explosion-

proof areas, etc.).

No possibility of failure because no sliding parts are used.

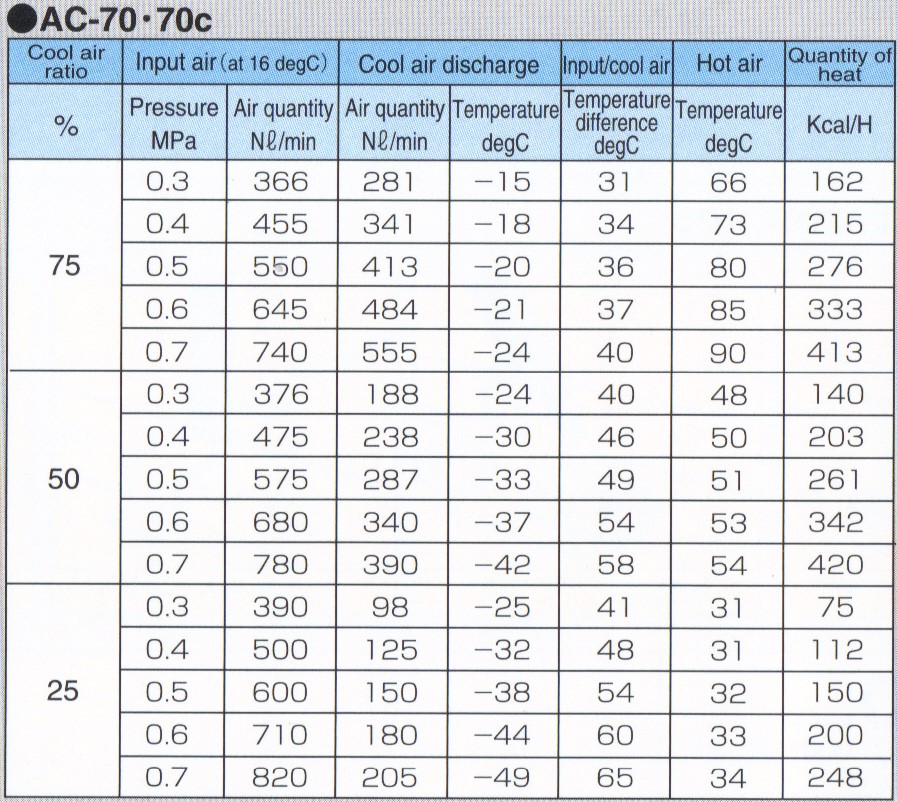

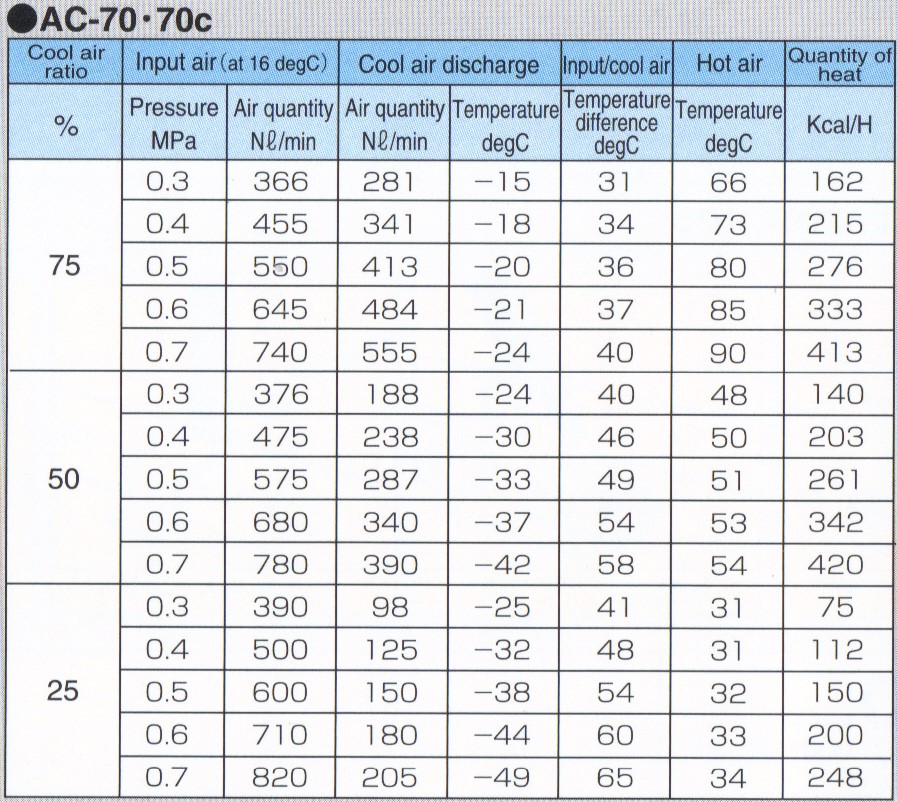

Specification of AC-70C

Specification of AC-70C

Specification of AC-70C

Specification of AC-70C